In the rapidly evolving landscape of artificial intelligence, the emergence of generative models has sparked a new wave of creativity and innovation. While text-based models (1D) and image generation (2D) have made remarkable advancements, the potential of generative AI in the realm of 3D modeling remains largely untapped, particularly in industries reliant on physical prototyping.

Ma’maar, by the AI team at QUIDS, focuses on integrating artificial intelligence with 3D printing to enhance Rapid Prototyping. We recognized that traditional design methods, although effective, can be challenging for newcomers due to the complexities of CAD modeling and digital sculpting software. Our mission at Ma’maar is to simplify the design process to make it accessible to everyone, regardless of their skill level. We are committed to removing obstacles that hinder creativity.

Explore our initiatives further at our store.

A few months ago, motivated by curiosity and innovation, we embarked on a project to use generative AI in a novel application: recreating a missing bottle cap using AI. This task, while straightforward, served as a practical test to determine if AI could effectively handle the complexities of 3D printing and modeling.

Watch our video demonstration here.

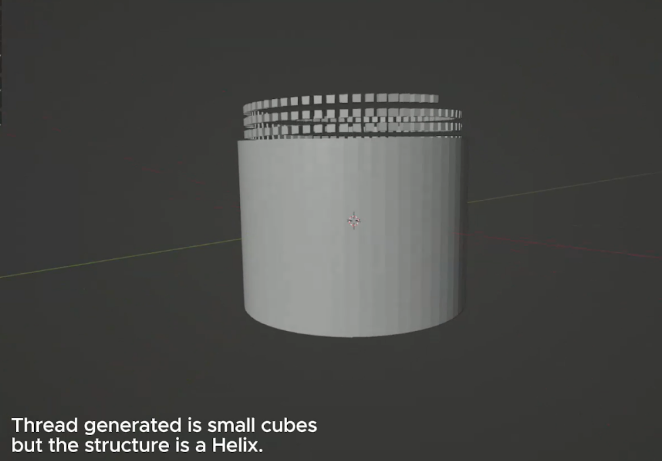

We initiated our experiment with the hypothesis that GPT could convert text into CAD scripts. Initially, we provided ChatGPT with the design specifications for a bottle cap to generate Blender scripts. While ChatGPT successfully captured the basic structure and dimensions of the cap, it struggled to script the threads accurately.

We continued to refine the prompt and tested various iterations. Eventually, we managed to create a helical structure, though it was nonfunctional and chatGPT repeatedly got the placement wrong.

Understanding the nuances of ChatGPT and the importance of context, we turned to an external resource, which provided code for the threads based on given specifications. The code generated threads with correct dimensions but incorrect orientation, requiring further adjustments.

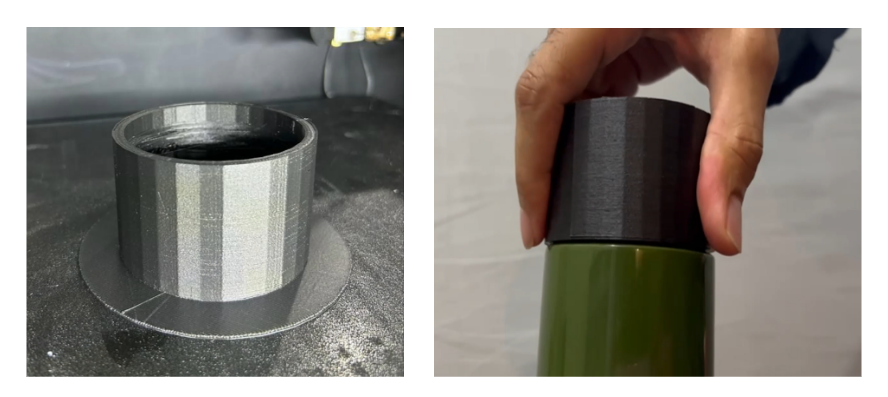

The final stage involved our modeling expert, who efficiently corrected the thread orientation. This adjustment was straightforward and could be managed by a beginner with proper guidance.

Here is what the final version looked like:

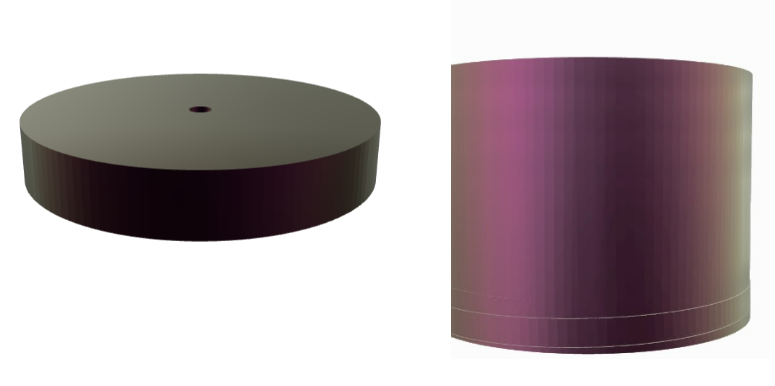

In our quest to explore the potential of generative AI in 3D modeling, we also conducted a comparative analysis with another similar generative platform, aiming to gauge the effectiveness and efficiency of our approach.

The platform we selected had capabilities in generating 3D models using Text to CAD similar to those we had employed and our initial expectations were high, surrounding its AI-driven design capabilities. We were hoping to witness comparable results to those achieved through our own experimentation.

The platform struggled to accurately capture intricate details, particularly when it came to the finer elements of the bottle cap design, such as the threading mechanism. Despite providing detailed specifications and prompts, the generated models consistently fell short of our expectations.

Here are the results:

In conclusion, our experience with generative AI in 3D modeling has been both informative and beneficial. Our experiments have demonstrated the significant potential of generative AI to address design challenges, yet our comparative analysis reveals that there are still substantial opportunities for advancement in this evolving field.

While there has been notable progress in using AI to create functional prototypes, a gap remains in accurately capturing detailed features essential for these prototypes.

At Quids, we are dedicated to advancing the capabilities of generative AI. We believe that continued innovation and teamwork will drive further improvements in this technology and its applications across various industries.